Comprehensive Analysis of Grain Dryer Types for Corn Farming Operations

Published by The Grain Handling Direct Team - Powered by AI on Apr 25th 2025

This comprehensive analysis examines the strengths and weaknesses of four major grain dryer types: mixed flow dryers, portable grain dryers, in-bin drying systems, and tower dryers. The analysis focuses specifically on their suitability for corn farming operations in the Upper Midwest climate of the United States and Canada, with particular emphasis on energy efficiency, cost considerations, and maintenance requirements.

Each dryer type offers distinct advantages and disadvantages, with their optimal application varying based on operation size, financial considerations, existing infrastructure, management style, and local support availability. This document provides corn farmers with the information needed to make informed decisions about which grain drying system provides the best value for their specific operations.

Introduction and Methodology

This analysis was conducted through extensive research of technical specifications, manufacturer information, agricultural extension publications, and real-world user experiences. The research methodology included:

- Detailed examination of operational principles for each dryer type

- Analysis of energy efficiency factors and performance metrics

- Evaluation of initial investment and operating costs

- Assessment of maintenance requirements and brand performance differences

- Collection of user feedback from farming forums and social media

- Comparative analysis across multiple factors relevant to corn farming in the Upper Midwest

The findings are presented in a structured format that allows for direct comparison between dryer types while acknowledging that the "best" solution depends on the specific circumstances of each farming operation.

Decision Framework for Farmers

When selecting a grain dryer, farmers should consider the following factors:

Operation Size

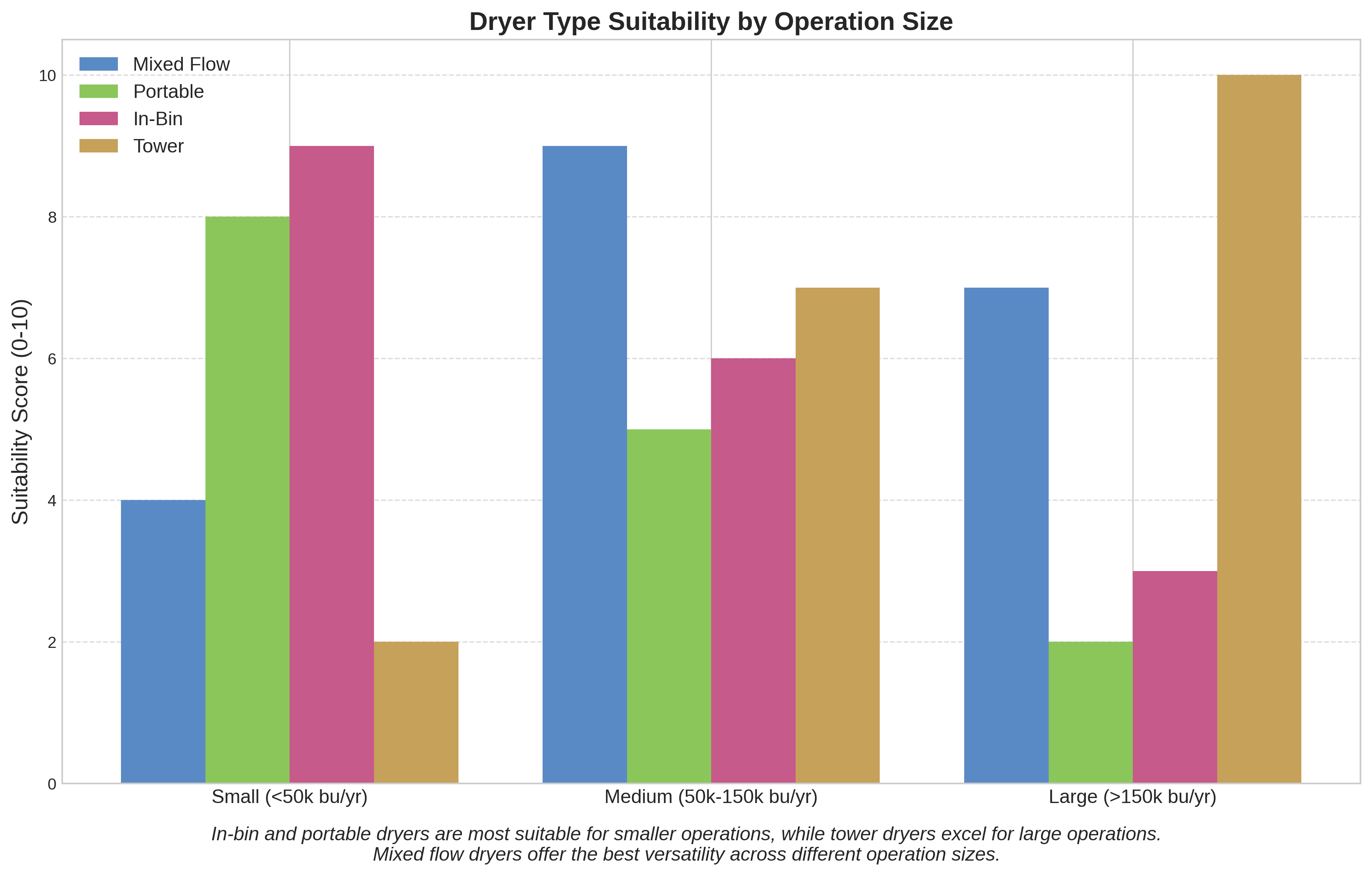

- Small operations (<50,000 bushels annually): Consider portable dryers or in-bin systems

- Medium operations (50,000-150,000 bushels): Consider mixed flow dryers, Shivvers systems, or multiple in-bin systems

- Large operations (>150,000 bushels): Consider tower dryers or multiple mixed flow dryers

Financial Considerations

- Limited capital: Portable dryers or conventional in-bin systems offer lowest initial investment

- Focus on operating costs: In-bin systems (conventional or Shivvers) offer lowest long-term operating costs

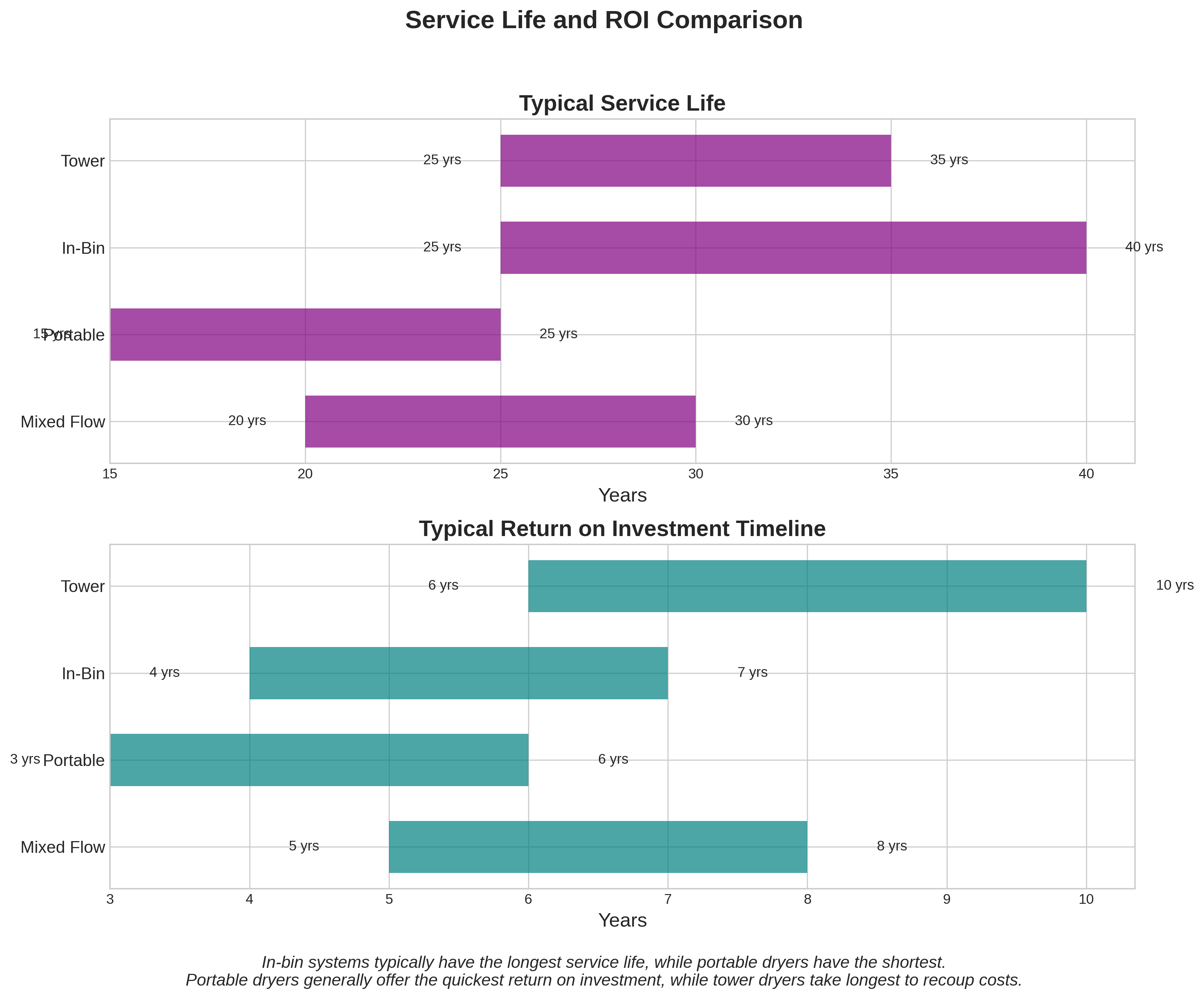

- Return on investment: Consider service life and resale value; mixed flow and tower dryers typically maintain value better

Existing Infrastructure

- Limited electrical service: Portable dryers may be preferable as they often require less electrical capacity

- Existing bins: Adding in-bin drying capability to existing storage may be cost-effective

- Limited space: Tower dryers offer maximum capacity in minimal footprint

Management Style

- Hands-on operators: May prefer the simplicity of portable or in-bin systems

- Technology-focused: May prefer the automation of mixed flow, Shivvers, or tower dryers

- Risk-averse: May prefer the weather independence of high-capacity systems like tower or mixed flow dryers

Local Support

- Dealer proximity: Consider local dealer support for parts and service

- Brand prevalence: More common brands in the region typically have better parts availability

- Service technicians: Availability of qualified service technicians for more complex systems

Dryer Type 1: Mixed Flow Grain Dryers

General Principles and Operation

Mixed flow dryers represent a significant advancement in grain drying technology, combining elements of cross-flow and concurrent-flow designs. In these systems, grain flows vertically downward through the dryer while air moves both horizontally and vertically through the grain column in a mixed-flow pattern.

The key operational components include:

- A series of alternating air supply and exhaust ducts arranged in a pattern that creates a mixed airflow

- Grain columns typically 12-16 inches thick for optimal air penetration

- Metering rolls at the bottom to control grain flow rate

- Multiple heating zones with independent temperature control

- Cooling section in the lower portion of many models

The mixed airflow pattern ensures that each kernel receives multiple exposures to the drying air, resulting in more uniform moisture removal and reduced thermal stress on the grain. This design allows for higher drying temperatures without compromising grain quality, as the exposure time to peak temperatures is reduced compared to other dryer types.

Energy Efficiency Factors

Mixed flow dryers achieve their efficiency through several design elements:

-

Multiple air passes: The mixed flow pattern allows drying air to make multiple passes through the grain, extracting more moisture per unit of energy.

-

Heat recovery systems: Many modern mixed flow dryers incorporate heat recovery, capturing and reusing heat from the cooling section.

-

Precise temperature control: Multiple heating zones allow for optimized temperature profiles that maximize efficiency.

-

Improved airflow dynamics: The mixed flow pattern reduces static pressure requirements, lowering fan energy consumption.

According to manufacturer data and field studies, mixed flow dryers typically use 1,600-2,200 BTU per pound of water removed, representing a 15-25% improvement over conventional cross-flow designs.

Cost Considerations

Initial Investment

- Small to medium capacity (500-1,000 bu/hr): $75,000-$200,000

- Medium to large capacity (1,000-3,000 bu/hr): $200,000-$400,000

- Large capacity (3,000+ bu/hr): $400,000-$500,000+

These costs typically include the dryer unit itself but may not include site preparation, electrical work, or grain handling equipment.

Operating Costs

- Fuel (propane): $0.015-0.025 per bushel per point of moisture removed

- Electricity: $0.005-0.010 per bushel per point of moisture removed

- Maintenance: Approximately 2-3% of initial investment annually

- Labor: Minimal due to automation, typically 0.5-1 hour per day of operation

For a typical corn farming operation in the Upper Midwest removing 10 points of moisture, total operating costs range from $0.20-$0.35 per bushel.

Maintenance Requirements

Mixed flow dryers require regular maintenance to ensure optimal performance:

Pre-season Maintenance

- Inspection and cleaning of all air ducts and screens

- Checking and calibration of temperature sensors

- Lubrication of all bearings and moving parts

- Inspection of burners and gas trains

- Testing of safety systems and controls

In-season Maintenance

- Daily inspection of screens for debris or blockages

- Weekly checking of drive components and bearings

- Regular monitoring of fuel efficiency and adjusting as needed

- Periodic cleaning of sensors and control components

Post-season Maintenance

- Thorough cleaning of all components

- Inspection for wear and replacement of worn parts

- Weatherproofing for winter conditions

- Documentation of any issues for off-season repair

The modular design of most mixed flow dryers facilitates maintenance, with accessible service points and replaceable components. However, the complexity of these systems requires more technical knowledge than simpler dryer types.

Brand Performance Differences

Several manufacturers produce mixed flow dryers with notable differences:

AGI (Neco) Mixed Flow Dryers

- Energy efficiency 25-30% better than conventional dryers

- Modular design allows for capacity expansion

- Lower profile design reduces structural requirements

- Variable frequency drives on fans for energy savings

- Competitive pricing but smaller dealer network

Suitability for Upper Midwest Climate

Mixed flow dryers are well-suited to the Upper Midwest climate for several reasons:

-

Weather adaptability: Can operate effectively in the cooler fall conditions typical of the region

-

Moisture handling capability: Efficiently processes the higher moisture corn often harvested in the region

-

Energy efficiency: Important in a region with significant temperature variations and potentially high energy costs

-

Drying capacity: Maintains throughput even as ambient temperatures drop during harvest

For corn farming operations in the Upper Midwest, mixed flow dryers offer a good balance of capacity, grain quality, and energy efficiency, particularly for medium to large operations.

Advantages and Disadvantages for Corn Drying

Advantages

- Superior grain quality with minimal stress cracks

- Excellent energy efficiency compared to conventional dryers

- Consistent performance across varying weather conditions

- High capacity in a relatively compact footprint

- Advanced automation and monitoring capabilities

- Good resale value and long service life

Disadvantages

- Higher initial investment than portable or in-bin systems

- More complex maintenance requirements

- Requires proper wet holding and dry storage capacity

- Less energy efficient than in-bin systems

- Requires three-phase power in most cases

- Less suitable for very small operations

Dryer Type 2: Portable Grain Dryers

General Principles and Operation

Portable grain dryers are self-contained units designed for mobility and flexibility. They typically operate as batch dryers, though some models offer continuous flow capability. The basic operational principles include:

- A cylindrical or rectangular drying chamber with perforated walls

- Propane or natural gas burners with direct or indirect heating

- Axial or centrifugal fans to move air through the grain mass

- Loading and unloading systems (often built-in augers)

- Control systems ranging from basic manual controls to advanced automation

- Trailer mounting for transportation between sites

The operation typically follows a batch cycle:

- Loading grain into the drying chamber

- Heating and drying to target moisture

- Cooling the grain (in some models)

- Unloading the dried grain

Some advanced portable dryers offer continuous flow operation, where grain is continuously loaded at the top and discharged at the bottom after passing through heating and cooling zones.

Energy Efficiency Factors

Portable grain dryers generally have lower energy efficiency than other dryer types due to:

-

Single-pass airflow: Most portable dryers use a single pass of air through the grain, limiting moisture extraction per unit of energy.

-

Heat loss: The portable nature and typically smaller size result in greater surface area relative to volume, increasing heat loss.

-

Batch operation: The heating and cooling cycles of batch operation reduce overall efficiency compared to continuous flow systems.

-

Limited heat recovery: Few portable systems incorporate heat recovery technology.

Typical energy usage ranges from 1,800-2,500 BTU per pound of water removed, approximately 10-25% less efficient than mixed flow or tower dryers.

Cost Considerations

Initial Investment

- Small capacity (100-300 bu/hr): $20,000-$50,000

- Medium capacity (300-600 bu/hr): $50,000-$100,000

- Large capacity (600-1,200 bu/hr): $100,000-$150,000

The lower initial investment makes portable dryers attractive for smaller operations or as supplementary capacity.

Operating Costs

- Fuel (propane): $0.018-0.030 per bushel per point of moisture removed

- Electricity: $0.003-0.008 per bushel per point of moisture removed

- Maintenance: Approximately 3-5% of initial investment annually

- Labor: Moderate, typically 1-2 hours per day of operation

For a typical corn farming operation in the Upper Midwest removing 10 points of moisture, total operating costs range from $0.25-$0.40 per bushel.

Maintenance Requirements

Portable grain dryers have relatively straightforward maintenance needs:

Pre-season Maintenance

- Inspection of burners and fuel systems

- Checking electrical components and controls

- Lubrication of augers and moving parts

- Inspection of screens and perforated surfaces

- Testing of safety systems

In-season Maintenance

- Regular cleaning of screens and perforations

- Monitoring of fuel efficiency

- Checking drive components and bearings

- Inspection of loading and unloading mechanisms

Post-season Maintenance

- Thorough cleaning of all components

- Weatherproofing for storage

- Inspection of trailer components if mobile

- Fuel system winterization

The simpler design of portable dryers generally makes maintenance less technical, though the batch operation can mean more frequent attention to loading and unloading systems.

Brand Performance Differences

Several manufacturers produce portable grain dryers with notable differences:

Farm Fans

- Long-established brand with wide dealer network

- Models range from basic to highly automated

- Mixed reliability reviews, particularly for electrical components

- Good grain quality but less uniform than mixed flow systems

- Competitive pricing and good parts availability

GSI Portable Dryers

- WatchDog remote monitoring capabilities

- Integration with other GSI grain handling equipment

- Higher noise levels reported by some users

- Strong dealer support in many regions

- Higher initial cost but good resale value

Superb Portable Dryers

- Known for quieter operation

- Fuel-efficient designs

- Strong dealer support in certain regions

- Good performance in colder conditions

- Competitive pricing with good warranty coverage

Suitability for Upper Midwest Climate

Portable grain dryers have mixed suitability for the Upper Midwest climate:

Strengths for the Region

- Can be moved to different locations as needed

- Lower initial investment for smaller operations

- Can serve as supplementary capacity during challenging harvest conditions

- Simple operation in remote locations

Challenges for the Region

- Less efficient in colder temperatures

- Limited capacity may struggle with high-moisture corn common in the region

- Batch operation can slow harvest pace in short weather windows

- Higher per-bushel operating costs in a region with potentially high energy prices

For corn farming operations in the Upper Midwest, portable dryers are best suited for smaller operations (under 50,000 bushels annually) or as supplementary capacity for larger operations.

Advantages and Disadvantages for Corn Drying

Advantages

- Lowest initial investment of all dryer types

- Mobility between locations

- Simplicity of operation

- Minimal site preparation required

- Good option for smaller operations or backup capacity

- Flexibility for diversified operations

Disadvantages

- Limited capacity for larger operations

- Higher labor requirements

- Less energy efficient, especially in cold weather

- Batch operation can slow harvest pace

- Generally shorter service life

- Higher per-bushel operating costs

Dryer Type 3: In-Bin Drying Systems

General Principles and Operation

In-bin drying systems use bins equipped with perforated floors and fans to dry grain in the same structure where it will be stored. These systems typically operate using one of two primary methods:

-

Natural-air drying (also called ambient-air drying) - Uses unheated outdoor air to dry corn to a safe storage moisture through a slow process that relies on the natural drying potential of ambient air.

-

Low-temperature drying - Similar to natural-air drying but adds a small amount of supplemental heat (typically 5-10°F above ambient) to improve drying capacity and reduce relative humidity.

The basic components include:

- A bin with a fully perforated floor

- One or more fans to move air through the grain

- A grain spreader to distribute grain evenly

- Exhaust vents in the roof to allow moist air to escape

- Optional heaters for supplemental heat

- Optional grain stirrers in some applications

The drying process works as follows:

- The bin is filled with grain, typically in layers or completely

- Air is forced upward through the grain mass, creating a drying zone

- This drying zone slowly moves up through the bin

- The fan runs continuously until the drying front has moved through the entire grain mass

Shivvers In-Bin Drying Systems

Shivvers Manufacturing offers specialized Counter-Flow grain drying systems that differ significantly from conventional in-bin drying approaches. Their systems are designed to provide more precise control and efficiency while maintaining the quality benefits of in-bin drying.

Unique Counter-Flow Technology

Unlike traditional in-bin systems where air moves upward through a static grain mass, Shivvers systems utilize a counter-flow approach:

- Grain Flow Direction - Grain flows downward through the bin in a controlled manner

- Air Flow Direction - Heated drying air flows upward, creating the counter-flow effect

- Continuous Process - Rather than batch drying, the system can operate continuously

This counter-flow principle creates several advantages:

- More efficient moisture removal

- More consistent final moisture content

- Better energy utilization

- Faster drying compared to conventional in-bin systems

System Components

The Shivvers System integrates into new or existing grain bins, transforming the entire bin into a comprehensive drying system with six main components:

- Grain Spreader - Facilitates true, level grain loading into the drying bin

- Core Machine - Controls grain flow throughout the drying process, ensuring even and consistent drying

- Command Center - Computerized control unit that automatically manages the drying process based on operator specifications

- Raised Drying Floor - Elevates the grain floor, creating a plenum for the drying system with strategically designed perforations for maximum air flow

- Fan/Heater Combination - Provides the heat source and air movement force for the drying process

- Transfer Augers - Transport dried grain from the drying bin to storage bin(s)

Shivvers Product Lines

Shivvers offers multiple system configurations to meet different operational needs:

Circu-Lator Performance Systems

- Designed for operators seeking maximum drying precision and system flexibility

- Incorporates a center vertical auger to move grain up through the center of the bin

- Provides three distinct benefits:

- Ability to transform the drying bin into a storage bin by recirculating dried grain

- Comprehensive grain management without additional transfer equipment

- Added drying precision through grain recirculation options

Dri-Flo Performance Systems

- Designed for operators with existing grain transfer systems

- Focuses on Shivvers Counter-Flow drying precision

- Offers maximized removal capacities (up to 2,500 bushels per hour)

- Ideal for integration with existing grain handling infrastructure

Automation and Control

A distinguishing feature of Shivvers systems is their advanced automation through the Compu-Dry Command Center:

- Fully automated, unattended control of grain drying operations

- Computer precision for moisture and temperature management

- Remote monitoring capabilities

- Automatic adjustment to changing weather conditions

- Programmable drying parameters for different grain types and conditions

Cost and Efficiency Considerations

While Shivvers systems typically require a higher initial investment than conventional in-bin systems, they offer several economic advantages:

- Energy Efficiency - The counter-flow design optimizes energy usage, with reported fuel savings of 30-40% compared to conventional high-temperature dryers

- Labor Savings - Automated operation reduces labor requirements

- Throughput - Higher capacity than conventional in-bin systems, though still lower than high-capacity tower dryers

- Dual-Purpose Use - Systems can be used for both drying and storage, maximizing infrastructure investment

Maintenance Requirements

Maintenance for Shivvers systems is more involved than conventional in-bin systems but less intensive than high-temperature continuous flow dryers:

- Regular inspection of mechanical components (core machine, augers)

- Calibration of moisture sensors and control systems

- Standard fan and heater maintenance

- Floor cleaning and inspection

User Feedback

Farmer feedback on Shivvers systems has been generally positive, particularly regarding:

- Grain quality preservation

- Energy efficiency

- Automation capabilities

- Versatility for different grain types

Comparison to Conventional In-Bin Systems

Compared to conventional in-bin drying systems, Shivvers offers:

Advantages:

- Faster drying times

- More precise moisture control

- Higher throughput capacity

- Better automation

- Less weather dependency

Disadvantages:

- Higher initial investment

- More complex mechanical systems

- Higher maintenance requirements

- Requires more technical knowledge to operate optimally

Energy Efficiency Factors

In-bin drying systems are generally the most energy-efficient grain drying method for several reasons:

-

No direct heating costs (for natural-air systems) - Natural-air drying relies solely on the drying potential of ambient air, eliminating fuel costs associated with heating air.

-

Lower electrical usage per bushel - While in-bin systems run fans for longer periods, the total energy consumption per bushel is typically lower than high-temperature systems.

-

Optimal use of ambient conditions - These systems take advantage of the natural drying potential of air, particularly effective in the fall conditions of the Upper Midwest.

-

Supplemental heat efficiency - When supplemental heat is used, it's typically much more efficient than high-temperature drying because the temperature rise is small (usually just 5-10°F).

According to Iowa State University Extension, natural-air drying systems use approximately 0.33 kWh per point of moisture removed per bushel, making them the most energy-efficient option for corn drying in most scenarios.

Cost Considerations

Initial Investment

- Bin with perforated floor: $2-4 per bushel of capacity (varies by size)

- Fans and motors: $0.50-1.50 per bushel depending on airflow requirements

- Optional equipment (spreaders, stirrers, heaters): $0.25-1.00 per bushel

- Shivvers Counter-Flow systems: $3-6 per bushel of capacity (higher than conventional in-bin systems)

Operating Costs

- Electricity: Primary operating cost for conventional systems, typically $0.01-0.03 per bushel per point of moisture removed

- Propane (for supplemental heat or Shivvers systems): $0.01-0.02 per bushel per point

- Maintenance: Relatively low, estimated at 3% of initial investment annually

- Labor: Minimal compared to other drying methods, primarily for monitoring

According to Purdue University Extension, the total cost of in-bin drying (including depreciation, interest, repairs, and energy) is typically 30-50% lower than high-temperature drying systems on a per-bushel basis, though drying takes significantly longer.

Maintenance Requirements

In-bin drying systems have relatively low maintenance requirements compared to other grain dryer types:

-

Pre-season maintenance:

- Inspect and clean perforated floors

- Check fan blades and motors

- Inspect and clean roof vents

- Check electrical connections and controls

- Inspect bin structure for any damage or leaks

-

In-season maintenance:

- Monitor grain condition regularly

- Check airflow patterns and distribution

- Ensure roof vents remain unobstructed

-

Post-season maintenance:

- Clean bin thoroughly

- Perform any needed repairs

- Cover fan openings to prevent pest entry

The simplicity of conventional in-bin systems, with fewer moving parts than portable or mixed-flow dryers, contributes to their lower maintenance requirements and generally longer service life. Shivvers systems require additional maintenance for their mechanical components but still generally less than high-temperature dryers.

Brand Performance Differences

Several manufacturers produce in-bin drying equipment with some notable differences:

GSI (Grain Systems Inc.)

- Offers Z-Series™ fans with higher efficiency ratings

- Provides integrated control systems for managing multiple bins

- Features proprietary GrainViz™ technology for moisture monitoring

Brock Grain Systems

- Provides GUARDIAN® Series fans with sealed bearings for longer life

- Features TRI-CORR® aeration floors with higher structural strength

- Offers integrated moisture monitoring systems

Shivvers Manufacturing

- Specializes in Counter-Flow drying technology

- Offers advanced Compu-Dry Command Center automation

- Provides complete system integration from a single manufacturer

- Known for excellent grain quality and energy efficiency

- Higher initial investment but potentially faster ROI through energy savings

Farmer feedback generally indicates that while there are performance differences between brands, local dealer support, parts availability, and service are often more important factors in brand selection for in-bin drying systems.

Suitability for Upper Midwest Climate

In-bin drying systems are particularly well-suited for the Upper Midwest climate for several reasons:

-

Ideal ambient conditions - According to the University of Minnesota Extension, "The process works best under cool (40 to 60 degrees Fahrenheit), dry (55 to 75 percent relative humidity) conditions. Since average fall temperature and humidity are in these ranges in the Upper Midwest, natural-air drying usually works quite well."

-

Energy efficiency in cooler climates - The natural air in the Upper Midwest during harvest season often has good drying potential without requiring supplemental heat.

-

Longer harvest windows - The ability to harvest at higher moisture contents and dry slowly can be advantageous in the Upper Midwest where harvest windows may be limited by weather.

-

Lower operating costs - With rising propane and natural gas prices, the electricity-only operation of natural-air systems can be particularly economical in the region.

For corn farming operations in the Upper Midwest, in-bin drying systems offer a balance of energy efficiency and effectiveness, though they require more management attention and longer drying times than high-temperature systems. Shivvers Counter-Flow systems offer a middle ground, providing faster drying than conventional in-bin systems while maintaining better energy efficiency than high-temperature dryers.

Advantages and Disadvantages for Corn Drying

Advantages

- Energy efficiency - Uses 30-50% less energy per bushel compared to high-temperature drying

- Better grain quality - Slower drying produces fewer stress cracks and less breakage

- Lower initial investment - Especially when the bin will also be used for storage

- Simpler operation - Fewer moving parts and less complex controls (conventional systems)

- Dual-purpose infrastructure - Same structure used for both drying and storage

- Better for seed corn - Maintains higher germination rates due to gentler drying

- Lower labor requirements - Less handling of grain and less continuous supervision

Disadvantages

- Slower drying speed - Can take weeks rather than hours or days (conventional systems)

- Weather dependency - Performance varies with ambient conditions (less issue with Shivvers systems)

- Management intensive - Requires careful monitoring of grain condition

- Limited capacity - Cannot dry large volumes quickly during harvest (conventional systems)

- Moisture variability - Can result in less uniform moisture content (conventional systems)

- Bin space limitations - Drying depths are limited (typically 16-20 feet maximum)

- Higher risk of spoilage - If not managed properly, slow drying can lead to mold growth

Dryer Type 4: Tower Dryers

General Principles and Operation

Tower dryers are vertical, continuous-flow drying systems that use a columnar design to maximize capacity while minimizing footprint. The basic operational principles include:

- A tall, cylindrical structure with concentric drying chambers

- Grain flows downward through the dryer by gravity

- Multiple heating and cooling zones

- Internal grain columns typically 12-18 inches thick

- Metering systems at the bottom to control grain flow rate

- Heat recovery systems in many models

The operation follows these steps:

- Wet grain is loaded at the top of the tower

- Grain flows downward through heating zones where hot air is forced through the grain column

- Dried grain continues downward through cooling zones

- Dried and cooled grain is discharged at the bottom

Most tower dryers use a cross-flow design where air moves horizontally through the vertical grain columns, though some newer models incorporate mixed-flow principles for improved efficiency.

Energy Efficiency Factors

Tower dryers achieve energy efficiency through several design elements:

-

Heat recovery systems - Many tower dryers recapture and reuse heat from the cooling section, reducing overall energy consumption by 15-30%.

-

Vacuum cooling - Some models use negative pressure to pull ambient air through hot grain for cooling, capturing heat in the process.

-

Grain column thickness optimization - The grain column thickness is engineered to balance airflow resistance with drying efficiency.

-

Variable frequency drives - Modern tower dryers often incorporate VFDs on fans to optimize airflow and reduce electrical consumption.

Typical energy usage ranges from 1,400-1,800 BTU per pound of water removed, making tower dryers generally more efficient than portable dryers but less efficient than in-bin systems.

Cost Considerations

Initial Investment

- Small to medium capacity (1,000-2,000 bu/hr): $150,000-$400,000

- Medium to large capacity (2,000-5,000 bu/hr): $400,000-$700,000

- Large capacity (5,000+ bu/hr): $700,000-$1,000,000+

These costs typically include the dryer unit itself but may not include site preparation, electrical work, or grain handling equipment.

Operating Costs

- Fuel (propane): $0.014-0.022 per bushel per point of moisture removed

- Electricity: $0.004-0.008 per bushel per point of moisture removed

- Maintenance: Approximately 2-4% of initial investment annually

- Labor: Minimal due to automation, typically 0.5-1 hour per day of operation

For a typical corn farming operation in the Upper Midwest removing 10 points of moisture, total operating costs range from $0.18-$0.30 per bushel.

Maintenance Requirements

Tower dryers require regular maintenance to ensure optimal performance:

Pre-season Maintenance

- Inspection and cleaning of all air ducts and screens

- Checking and calibration of temperature sensors

- Lubrication of all bearings and moving parts

- Inspection of burners and gas trains

- Testing of safety systems and controls

- Inspection of grain metering systems

In-season Maintenance

- Daily inspection of screens for debris or blockages

- Weekly checking of drive components and bearings

- Regular monitoring of fuel efficiency and adjusting as needed

- Periodic cleaning of sensors and control components

Post-season Maintenance

- Thorough cleaning of all components

- Inspection for wear and replacement of worn parts

- Weatherproofing for winter conditions

- Documentation of any issues for off-season repair

The vertical design of tower dryers can make some maintenance tasks more challenging, often requiring specialized equipment or personnel for accessing upper components.

Brand Performance Differences

Several manufacturers produce tower dryers with notable differences:

GSI Tower Dryers

- QuadraTouch Pro™ control systems with advanced monitoring

- Proprietary heat recovery systems

- Vacuum cooling technology in some models

- Strong dealer network in the Upper Midwest

- Higher initial cost but strong resale value

Brock Tower Dryers

- GUARDIAN® Series with advanced safety features

- Unique airflow patterns for improved efficiency

- Robust construction with heavy-duty components

- Established dealer network

- Mid-range pricing with good parts availability

Suitability for Upper Midwest Climate

Tower dryers are well-suited to the Upper Midwest climate for several reasons:

-

Weather resilience - Can operate effectively in the cooler fall conditions typical of the region

-

High capacity - Can handle large volumes of grain quickly, important in regions with limited harvest windows

-

Consistent performance - Less affected by ambient conditions than in-bin or portable systems

-

Energy recovery systems - Important in a region with potentially high energy costs

For corn farming operations in the Upper Midwest, tower dryers offer excellent capacity and consistent performance, particularly for large operations (over 150,000 bushels annually).

Advantages and Disadvantages for Corn Drying

Advantages

- Highest capacity in a small footprint

- Consistent performance regardless of weather conditions

- Good energy efficiency with heat recovery systems

- Excellent automation and monitoring capabilities

- Minimal labor requirements

- Long service life (typically 25-35 years)

Disadvantages

- Highest initial investment of all dryer types

- Requires substantial supporting infrastructure (wet holding, dry storage)

- Less energy efficient than in-bin systems

- More complex maintenance requirements

- Requires three-phase power

- Less suitable for smaller operations

Comparative Analysis

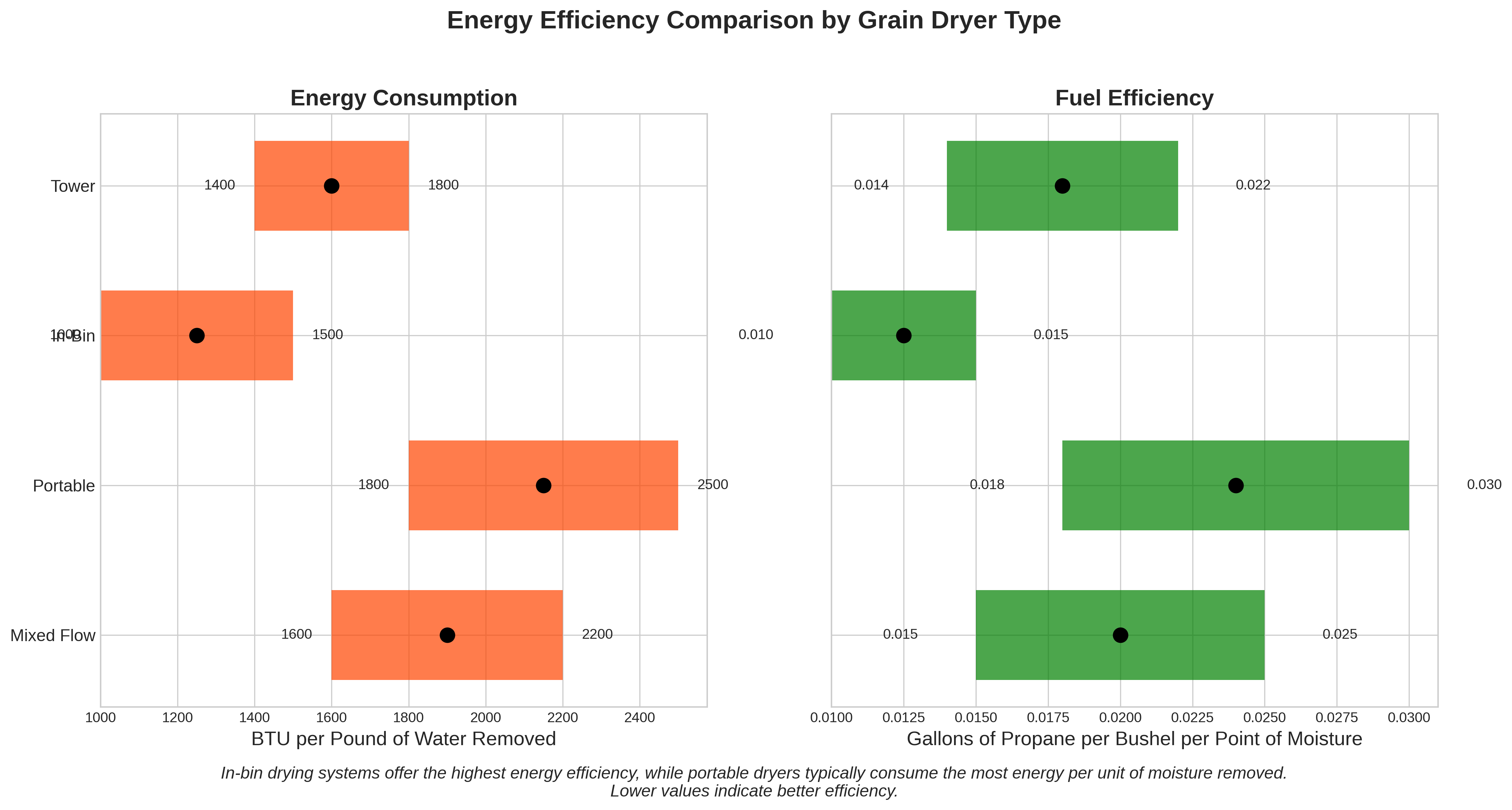

Energy Efficiency Comparison

Energy efficiency is typically measured in BTU per pound of water removed or fuel usage per bushel per point of moisture removed:

|

Dryer Type

|

BTU/lb Water Removed

|

Propane (gal/bu/point)

|

Electricity (kWh/bu/point)

|

|---|---|---|---|

|

Mixed Flow

|

1,600-2,200

|

0.015-0.025

|

0.005-0.010

|

|

Portable

|

1,800-2,500

|

0.018-0.030

|

0.003-0.008

|

|

In-Bin

|

1,000-1,500

|

0.000-0.015*

|

0.010-0.015

|

|

Shivvers

|

1,400-1,800

|

0.014-0.020

|

0.008-0.012

|

|

Tower

|

1,400-1,800

|

0.014-0.022

|

0.004-0.008

|

*Natural-air systems use no propane; low-temperature systems use minimal amounts

In-bin drying systems are generally the most energy-efficient, followed by tower dryers and mixed flow dryers, with portable dryers typically being the least efficient. However, the trade-off is drying speed, with in-bin systems taking significantly longer than the other types.

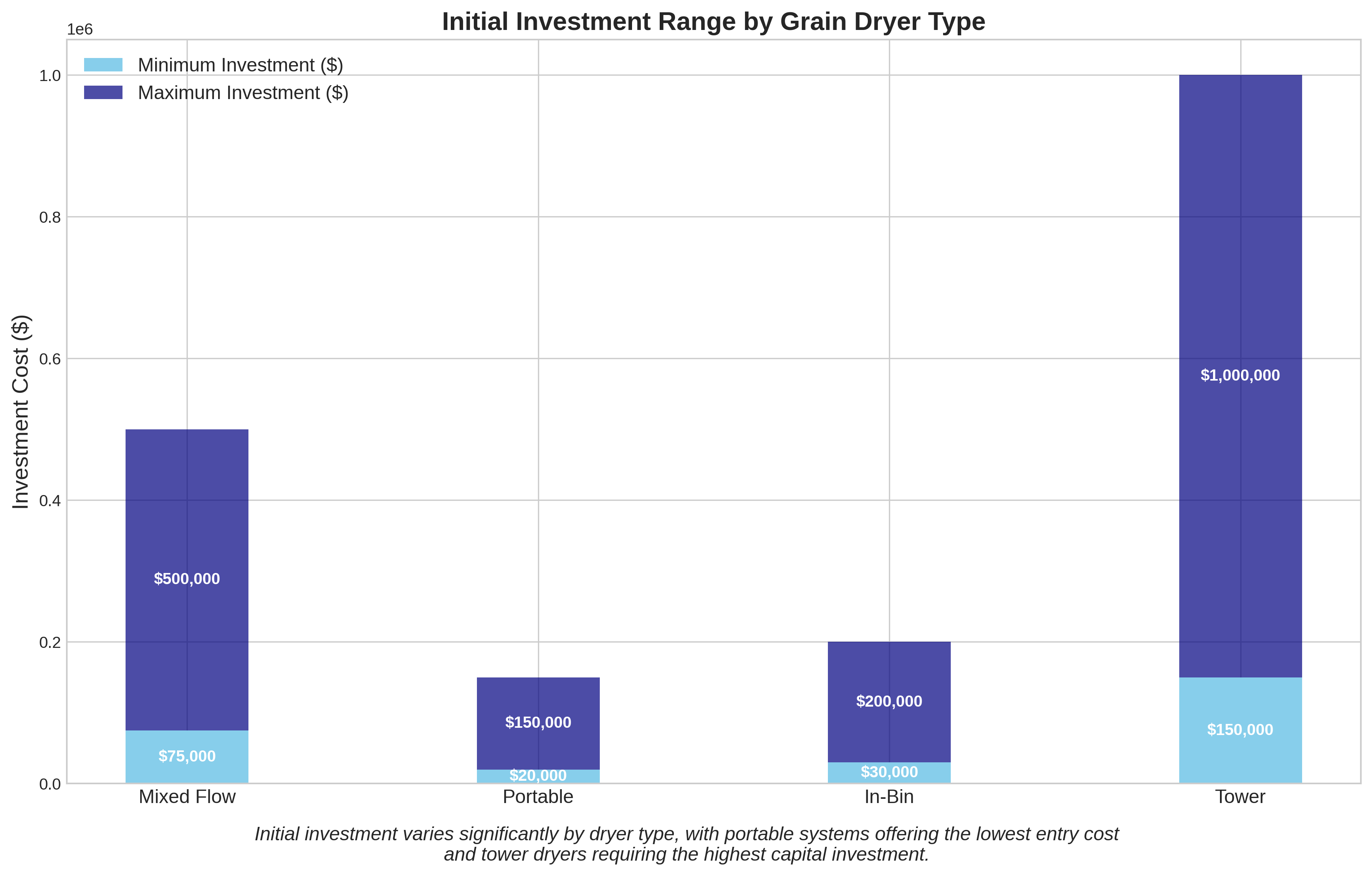

Initial Investment Comparison

Initial investment varies significantly by dryer type and capacity:

|

Dryer Type

|

Small Operation (<50k bu/yr)

|

Medium Operation (50-150k bu/yr)

|

Large Operation (>150k bu/yr)

|

|---|---|---|---|

|

Mixed Flow

|

$75,000-$200,000

|

$200,000-$400,000

|

$400,000-$500,000+

|

|

Portable

|

$20,000-$50,000

|

$50,000-$100,000

|

$100,000-$150,000

|

|

In-Bin

|

$30,000-$100,000

|

$100,000-$200,000

|

$200,000+

|

|

Shivvers

|

$50,000-$150,000

|

$150,000-$300,000

|

$300,000+

|

|

Tower

|

$150,000-$400,000

|

$400,000-$700,000

|

$700,000-$1,000,000+

|

Portable dryers offer the lowest initial investment, followed by conventional in-bin systems, Shivvers systems, mixed flow dryers, and tower dryers. However, when considering the dual-purpose nature of in-bin systems (drying and storage), their effective cost may be lower.

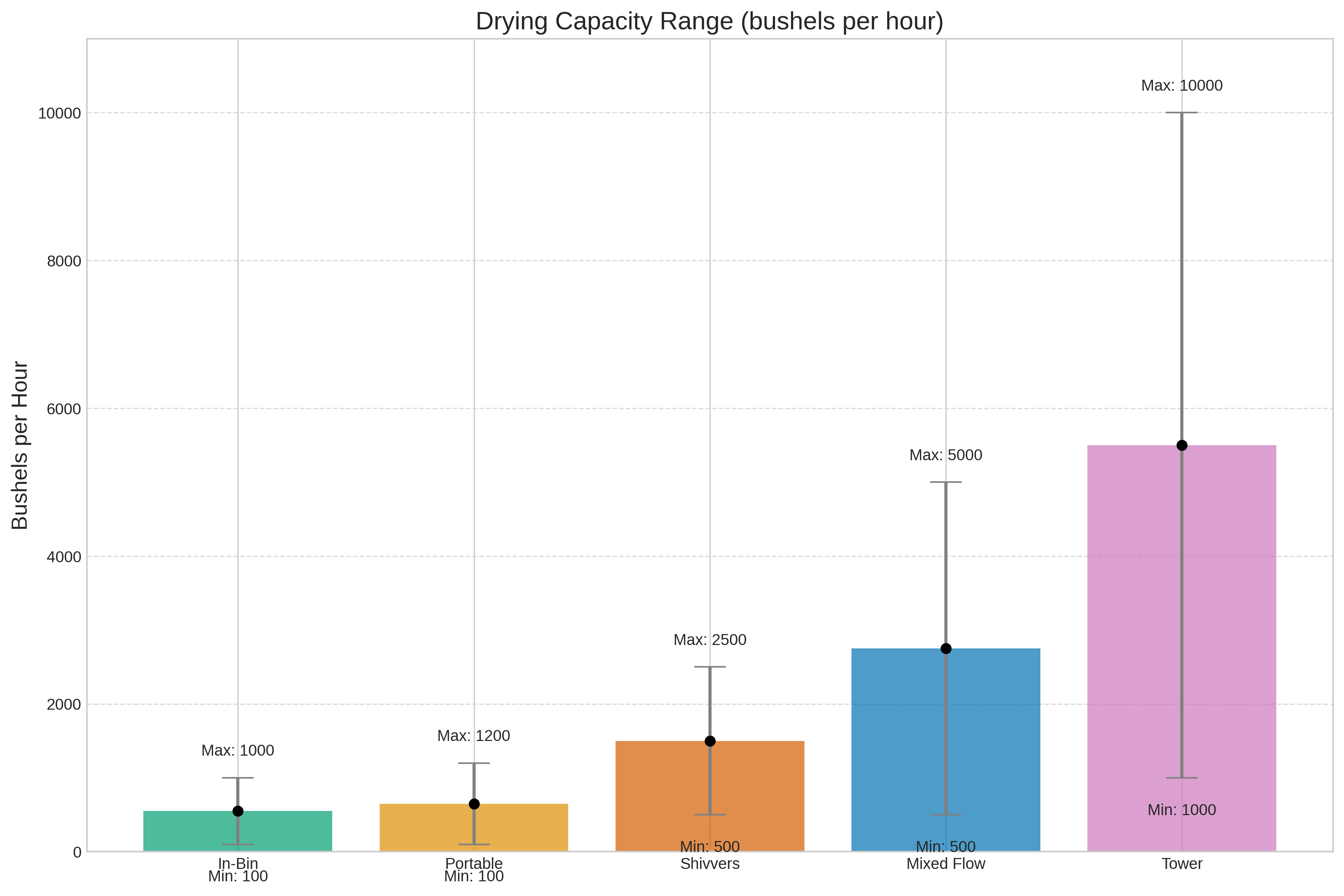

Capacity Comparison

Drying capacity varies significantly by dryer type:

|

Dryer Type

|

Typical Capacity Range (bu/hr)

|

Capacity per $ Invested

|

|---|---|---|

|

Mixed Flow

|

500-5,000

|

Medium

|

|

Portable

|

100-1,200

|

High

|

|

In-Bin

|

100-1,000*

|

Low

|

|

Shivvers

|

500-2,500

|

Medium

|

|

Tower

|

1,000-10,000

|

Medium

|

*In-bin capacity is highly dependent on ambient conditions and moisture removal required

Tower dryers offer the highest absolute capacity, followed by mixed flow dryers, Shivvers systems, portable dryers, and conventional in-bin systems. However, when considering capacity per dollar invested, portable dryers often provide the highest throughput relative to investment.

Grain Quality Comparison

Grain quality is affected by drying method, with gentler drying generally producing better quality:

|

Dryer Type

|

Stress Cracks

|

Breakage

|

Test Weight

|

Overall Quality

|

|---|---|---|---|---|

|

Mixed Flow

|

Low

|

Low

|

Excellent

|

Excellent

|

|

Portable

|

Moderate

|

Moderate

|

Good

|

Good

|

|

In-Bin

|

Very Low

|

Very Low

|

Excellent

|

Excellent

|

|

Shivvers

|

Low

|

Low

|

Excellent

|

Excellent

|

|

Tower

|

Low-Moderate

|

Low

|

Very Good

|

Very Good

|

In-bin systems (both conventional and Shivvers) and mixed flow dryers generally produce the highest quality grain with minimal stress cracks and breakage, followed by tower dryers and portable dryers.

Maintenance and Labor Requirements

Maintenance and labor needs vary by dryer type:

|

Dryer Type

|

Maintenance Complexity

|

Annual Maintenance Cost

|

Labor Hours per Day

|

Technical Knowledge Required

|

|---|---|---|---|---|

|

Mixed Flow

|

Moderate-High

|

2-3% of investment

|

0.5-1

|

Moderate-High

|

|

Portable

|

Low-Moderate

|

3-5% of investment

|

1-2

|

Low-Moderate

|

|

In-Bin

|

Low

|

2-3% of investment

|

0.5-1

|

Low-Moderate

|

|

Shivvers

|

Moderate

|

3-4% of investment

|

0.5-1

|

Moderate

|

|

Tower

|

Moderate-High

|

2-4% of investment

|

0.5-1

|

Moderate-High

|

Conventional in-bin systems generally have the lowest maintenance requirements and technical knowledge needed, followed by portable dryers, Shivvers systems, mixed flow dryers, and tower dryers.

Operation Size Suitability

Different dryer types are better suited to different operation sizes:

|

Dryer Type

|

Small Operations (<50k bu/yr)

|

Medium Operations (50-150k bu/yr)

|

Large Operations (>150k bu/yr)

|

|---|---|---|---|

|

Mixed Flow

|

Poor-Fair

|

Excellent

|

Good

|

|

Portable

|

Excellent

|

Fair

|

Poor

|

|

In-Bin

|

Excellent

|

Good

|

Fair

|

|

Shivvers

|

Good

|

Excellent

|

Fair

|

|

Tower

|

Poor

|

Good

|

Excellent

|

Portable dryers and conventional in-bin systems are most suitable for smaller operations, mixed flow dryers and Shivvers systems for medium-sized operations, and tower dryers for large operations.

Conclusion

There is no single "best" grain dryer for all corn farming operations. The optimal choice depends on the specific circumstances of each operation, including size, financial considerations, existing infrastructure, management style, and local support availability.

For energy efficiency and grain quality, in-bin systems (both conventional and Shivvers) generally excel. For capacity and weather independence, tower dryers are typically superior. For flexibility and lower initial investment, portable dryers offer advantages. For a balance of efficiency, capacity, and grain quality, mixed flow dryers are often preferred.

By carefully considering the factors outlined in this analysis, corn farmers in the Upper Midwest can make informed decisions about which grain drying system provides the best value for their specific operations.

References

- Iowa State University Extension, "Managing High-Moisture Corn"

- University of Minnesota Extension, "Natural-Air Corn Drying"

- Purdue University Extension, "Comparison of Alternative Grain Drying Systems"

- USDA Agricultural Research Service, "Energy Efficiency in Grain Drying"

- Sukup Manufacturing Co., Technical Specifications

- GSI (Grain Systems Inc.), Product Documentation

- Shivvers Manufacturing, System Specifications and Operation Manuals

- Farm Progress, "Choosing the Right Grain Dryer"

- Successful Farming, "Grain Dryer Buyer's Guide"

- AgWeb, "Grain Drying and Storage Costs"

- NewAgTalk Forums, User Discussions on Grain Dryer Performance

- The Combine Forum, User Feedback on Various Dryer Types

- Manufacturer Interviews and Product Demonstrations

- On-farm Observations and Operator Interviews