Description

Portable Dryers

Increase yields and improve profits

Highlights

- Harvest your grain earlier at higher moisture levels and dry it in bins on the farm, increasing yields and improving profits.

- Shorten wait time during drying, minimize weather risks, reduce dry matter loses, and reduce head shatter loss.

- Single, double or triple module models available.

- All heat or Dry/Cool operation. LP or natural gas.

- Monitor performance and control from anywhere with GSI Connect.

Remote Dryer Management - Know your dryer a little less personally this harvest

Harvest is hectic. And the last thing you need is an extra trip to the dryer. With GSI Connect, you know your dryer is doing its job. So, you can stay where you are and keep doing yours.

- Control from anywhere

- See your dryer's status, moisture, temperature

- Adjust set points, stop your dryer and change unload speeds

- Monitor your dryer's performance and get alerts to reduce runtime and maximize profit

Best of all, portable dryers are just the beginning. GSI is working to make GSI Storage and Material Handling connect-ready too. So, with GSI Connect, you can put your entire grain system in your hands.

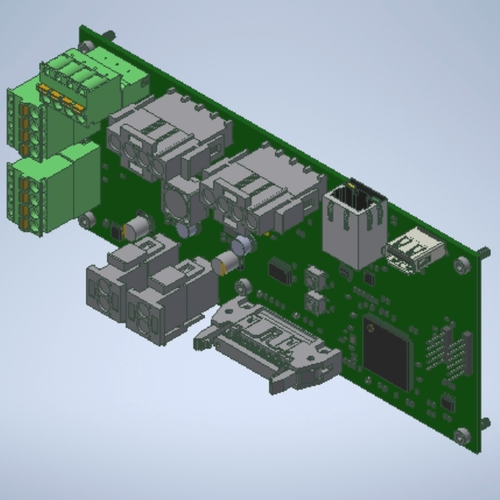

Vision Controls

Vision controls offer simple operation, with an easy-to-read large color graphical touch display. Located on the dryer or remote with a few wires, these controls are design specifically for GSI grain dryers, giving you unmatched options and settings to get exactly what you need from your dryer control.

The Vision Network Dryer Control system is designed to take the guesswork out of operating your GSI Portable Dryer. With a quick glance, you can see the operating status of the augers, fans and heaters on the large, easy-toread color touchscreen. On-screen temperature and moisture-based controls let you modify and manage plenum and grain temperatures quickly and easily.

FEATURES:

• 10.4” TFT color screen with touch screen control

• 32-Bit microprocessor control

• Standard with 13 diff erent language capabilities, including English, Spanish, French, German, Russian, Polish, Portuguese, Dutch, Danish, Bulgarian, Czech, Hungarian and Romanian.

• Plenum temperature manager

• Individual safety monitoring with status displayed on-screen

• Shut-downs logged with time and date

• Safety disconnect on every dryer

• Low voltage safety circuit

• Includes hour meter Includes hour meter

WATCHDOG™

The smartphone-compatible WatchDog provides remote dryer control and monitoring, with the same Vision interface you use on your dryer unit.

DRYER START-UP MADE EASY

What used to take two to four hours can now be done automatically. Simply input the incoming moisture of the grain, desired outgoing moisture and the grain type and hit start. Vision Auto-Start will manage and control the pre-drying of the grain and stage the operation of the dryer.

AC METERING ROLLS AND ADJUSTABLE FLOW GATES

A 4” AC variable frequency drive metering roll smoothly transitions grain from your dryer to

your handling system. When grain quality is poor and debris is present, adjustable flow gates

allow you to customize control of grain volume in each column for more consistent drying. An optional upgrade to a 7” meter roll system does not require the use of gates.

STATIC MOISTURE SAMPLER

Takes readings only when the grain is static and not flowing. Using GSI’s patented discharge auger to ensure that a true cross section of the grain is sampled, a reading is taken once per minute and the dryer automatically adjusts to provide optimal results.

EVEN HEAT AND GRAIN QUALITY

High/Low fire cycling helps to maintain a uniform plenum temperature. Each plenum chamber also has an air-mixing chamber to thoroughly mix the air and heat.

OPTIMIZED AIRFLOW

Airflow is sized to match the basket to achieve consistent airflow and capacity. Additional benefits include high air flow across a wide static pressure range, quiet operation and reduced energy cost.

HIGH EFFICIENCY BURNER

Provides even heat distribution and maximum airflow to the dryer’s plenum. An electronic ignition system monitors the burner and a view window provides for easy observation of the burner while in operation. Features include easy-to-adjust vaporizer, large service access door and oil-filled gas pressure gauges. Standard on GSI dryers, On/Off Fire offers a wider range of plenum temperature control down to five degrees above ambient temperature for wheat and other temperature-sensitive grains.

CONFIGURATION: Single module, single fan & heater with a single plenum. Not expandable. Available with either Vane Axial Fan or Quiet Blower (GSI Quiet Dryer).

APPLICATION: Small- to medium-sized farms using bins 50,000 bushels or less with adequate bin cooling air. Perfect as a first high speed dryer, the 1100 series delivers between 420 to 1,160 BPH All Heat drying at 5-point removal. While primarily an All Heat corn drying system, the 1100 Series dryer can also be used in Continuous Batch Dry & Cool operation full time or for specific situations – putting a dry cone in a flat bottom wet bin, or occasional soybean or wheat drying – to still be able to deliver cooled grain.

Model 1112 Selected Options

CONTROLS: Vision Touch Screen Controls, Electronic Flame Sensing, 3 Modes of Automatic Moisture Control. Continuous Flow, Batch and Multi-Stage Controls. Main Power Safety Disconnect. Powder Coated Control Cabinet, Double Sealed With See Through Door.

SCREENS: Drying Columns With Solid Dividers Every 2 Feet, .094" Perforations, Galvanized Steel Screens.

LOAD: Rear Fill (Std), Galvanized .094" Perforated Wet Bin with Standard Level Auger with DuraEdge Flighting Mounted on Oil-Impregnated Wood Hanger Bearings for Long Life and Dependability

UNLOAD: 7" Metering Roll System (VFD - AC Motor Driven), Lever Operated Dump Doors To Clean Out Discharge Auger. Rear Discharge (Std), with Standard 8" Auger with 1/4" DuraEdge Flighting for Fast Unloading and Longer Life

FAN(S): Low Speed - Qty 1 at 15 hp, 36" diameter

HEATER(S): Patented Blue Burn Optimizer, Hi-Lo Fire - Qty 1 at 4.5 million btu/hr

FUEL: Liquid Propane - Includes Internal Adjustable Vaporizer

POWER: 230 Volt, 3 Phase - 60 Hertz Electric Load 64 / 108 (Min/Max Amps) (Min: Fan, Load, Unload, No Auxiliaries; Max: Fan, Load, Unload, Max Auxiliaries)

AUXILIARIES: Load:7.5 hp (7.5 hp Std.) - Unload: 7.5 hp (7.5 hp Std.)

DIMENSIONS: 17 ft. 6 in. Installed Height (Foundation Surface - Top of Fill Box) using 36" Support Legs. 19 ft. 2 in. Installed Length by 8 ft. Installed Width.

(*Dimensions do not consider optional accessories such as Heat Reclaimer or Catwalks)

Transport Dimensions: 13 ft. 5 in. Height, 8 ft. Width, 21 ft. 2 in. Length

CAPACITY: Drying Capacity* Full Heat 20% to 15%: 530 BPH / 13.46 MTH Moisture Removal for Shelled Corn