Maintaining Your Grain Handling System: What To Know

Published by The Grain Handling Direct Team on Oct 12th 2022

The grain handling system and equipment are essential to quality farming and crop storage. If you’re new to grain handling systems or have had problems lately, our guide offers many maintenance tips and other things you should know to ensure your system works properly.

Why Grain Handling Maintenance Is Important

They say that a carpenter is only as good as his tools, and the same is true for farmers and their grain handling equipment. Efficiency and accuracy are essential to proper grain handling for many farmers, and faulty equipment and system can eat into profits and cause financial distress.

Plus, grain handling is dangerous, and faulty equipment is a safety hazard for workers and anyone near the grain handling system. Grain dust, in particular, is highly combustible and can burn or explode instantly from airborne accumulation and an ignition source from equipment and duties like conveyor belts or overheated equipment.

For many reasons, sufficient maintenance is essential in any grain handling operation.

Tips for Maintaining Your Grain Handling System

If you’re new to the grain handling system or have had problems in the past, we can help with our guide. Keep your equipment running smoothly and yourself and your workers safe while operating the grain handling system with our tips.

Clean Out Storage Bins

The most obvious but important advice we can offer about proper grain handling maintenance is to keep it as clean as possible as often as possible. Grain bins can be hotbeds for bacteria and pests if they’re not thoroughly cleaned after you’ve unloaded them and before you load a new haul of grain.

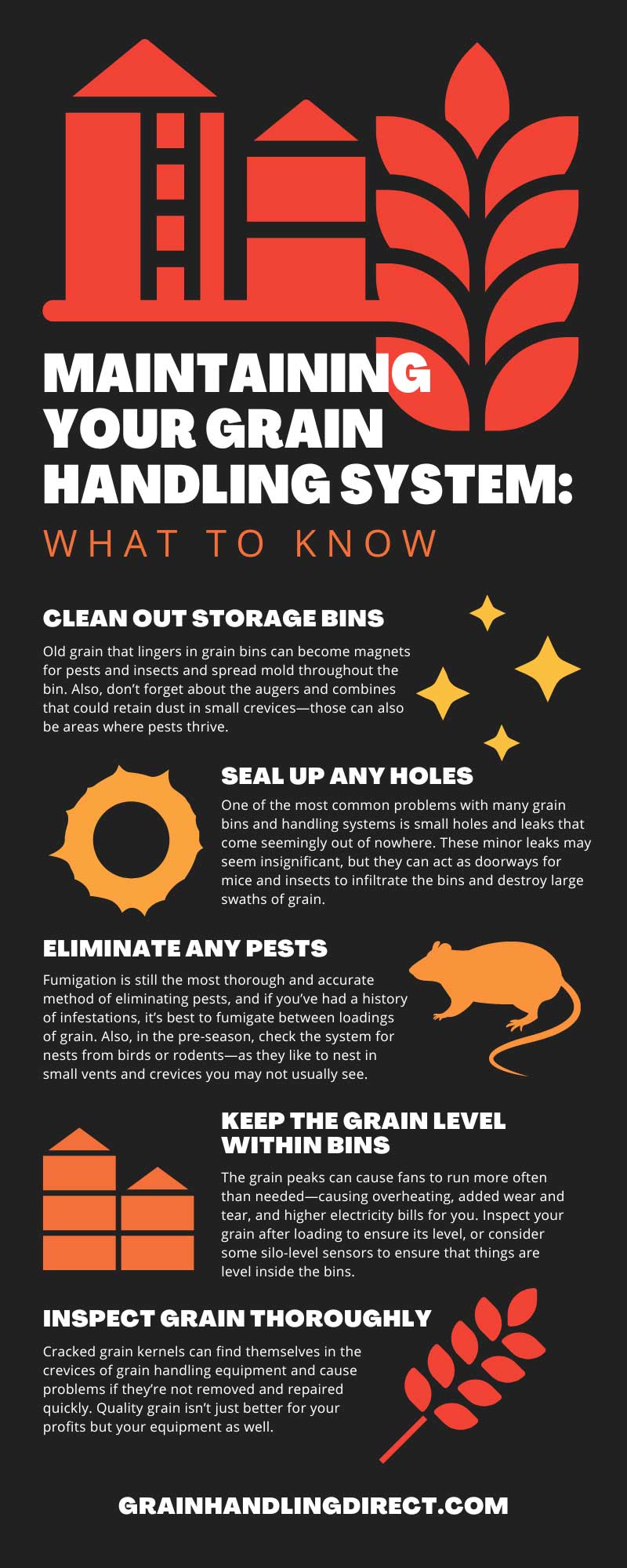

Old grain that lingers in grain bins can become magnets for pests and insects and spread mold throughout the bin. Also, don’t forget about the augers and combines that could retain dust in small crevices—those can also be areas where pests thrive.

Pro Tip

If you’ve had problems cleaning out the dust in your bins, consider a hopper with a built-in dust suppression system to mitigate dust accumulation.

Seal Up Any Holes

One of the most common problems with many grain bins and handling systems is small holes and leaks that come seemingly out of nowhere. These minor leaks may seem insignificant, but they can act as doorways for mice and insects to infiltrate the bins and destroy large swaths of grain.

These relatively minor holes are why thorough and close inspections of bins and equipment are crucial to maintaining the handling system. If you’ve been having problems with pests and mice, odds are it’s due to an unseen hole somewhere in the bin.

Pro Tip

Consider using an instant repair patch kit that can seal up small holes in minutes.

Eliminate Any Pests

Pests are perhaps a farmer’s greatest enemy as they can wreak havoc on grain and grain bins in no time. Once they’ve found a hole or leak in your system, pests can be disastrous and challenging to eliminate.

Fumigation is still the most thorough and accurate method of eliminating pests, and if you’ve had a history of infestations, it’s best to fumigate between loadings of grain. Also, in the pre-season, check the system for nests from birds or rodents—as they like to nest in small vents and crevices you may not usually see.

Pro Tip

Electrical components like control boxes are popular nesting spots for birds and animals, so check them regularly to ensure the wiring of your system isn’t gnawed to oblivion.

Repair Any Damaged Equipment Immediately

A grain handling system can’t work if it has damaged parts that require repairs. Many small parts of a grain handling system can break or get damaged—from the flow valves to the fans or grain belt conveyor.

Proper maintenance and repairs ensure that your equipment works adequately and lasts longer—giving you better value for your equipment investment. Even if the problems seem minor or unimportant, all it takes is one small issue for an entire system to fail quickly.

Keep the Grain Level Within Bins

Even the shape of the grain piles inside the bin can help keep the handling system running properly. When grain gets stored in peaks, it’s more difficult to monitor and gauge accurately for systems like drying fans.

The grain peaks can cause fans to run more often than needed—causing overheating, added wear and tear, and higher electricity bills for you. Inspect your grain after loading to ensure its level, or consider some silo-level sensors to ensure that things are level inside the bins.

Examine Belts & Bearings Regularly

In a grain handling system, many belts, bearings, and small things can wear out quickly and cause massive disruptions. It’s always wise to examine and inspect the small things in a large system that ensures everything runs smoothly.

Inspect and lubricate any chains that may require some grease and test the belts for proper tension throughout the system. Bearings on dryers and conveyors are notorious for seizing up, so ensure those components especially are sufficiently lubricated.

Inspect Grain Thoroughly

Even the grain itself can help ensure that the handling equipment works properly. Subpar grain is more likely to crack or produce mold—which can wreak the entire grain stock and disrupt the equipment.

Cracked grain kernels can find themselves in the crevices of grain handling equipment and cause problems if they’re not removed and repaired quickly. Quality grain isn’t just better for your profits but your equipment as well.

Strengthen the Foundation

Don’t forget the ground the grain bins stand on, either. A grain bin can hold thousands of pounds of grain without a problem if its foundation is strong and even.

The last thing any farmer wants is the ground beneath their bins falling away before them, so it’s always wise to strengthen the foundation before it starts to falter. Inspect the foundation regularly for any cracks or structural damage that could become a significant problem if neglected.

Create an Environmental Perimeter

The grain bin and foundation environment are crucial to maintaining your grain handling system. If you let the grass and nature grow wildly around grain bins, they can become breeding grounds for rodents, insects, and other animals that want to infiltrate your grain bins.

Mark a clear perimeter around the grain bins and keep them well-maintained to better keep pests away. Also, if the ground is uneven, it can cause water moisture buildup near the grain bin, which no one wants. If you have to, consider grading the perimeter around the grain bin to keep water at a safe distance.