Description

PROVEN & DEPENDABLE

Only GSI feed tanks feature the exclusive, patented Auto-Lok ground control access system for opening, closing and latching the fill cap safely and easily from the ground. The cap swings open a full 180° to lie flat and parallel to the ground, completely eliminating interference with, or damage to, the cap from the auger.

Bulk Feed Tanks also feature an optional hopper valve for for accessing small amounts of material to a location not serviced by the auger system.

GSI manufactures roofs from prime, high tensile, galvanized steel. The higher tensile steel adds up to 20% more strength, with no extra weight, which is critical in clear span roof structural design. Roof eave clearance can be adjusted at the time of installation. Each roll formed roof rib has four supportive bends in the vertical sides for maximum strength. Tall roof ribs are fully double overlapped for moisture resistance and additional support. The easy to open peak cap provides a large 30” diameter opening for fast filling.

GSI hopper tank support legs are manufactured from high tensile steel, 65,000 PSI (448 MPa), and completely galvanized for durability.

BULK FEED TANKS (BFT)

BFTs are a popular way of storing feed due to their ease of installation, lower expansion cost and convenient hopper unloading. Several of these tanks can be installed to store a variety of grains and the sealed roof and body design helps protect grain/feed from moisture damage.

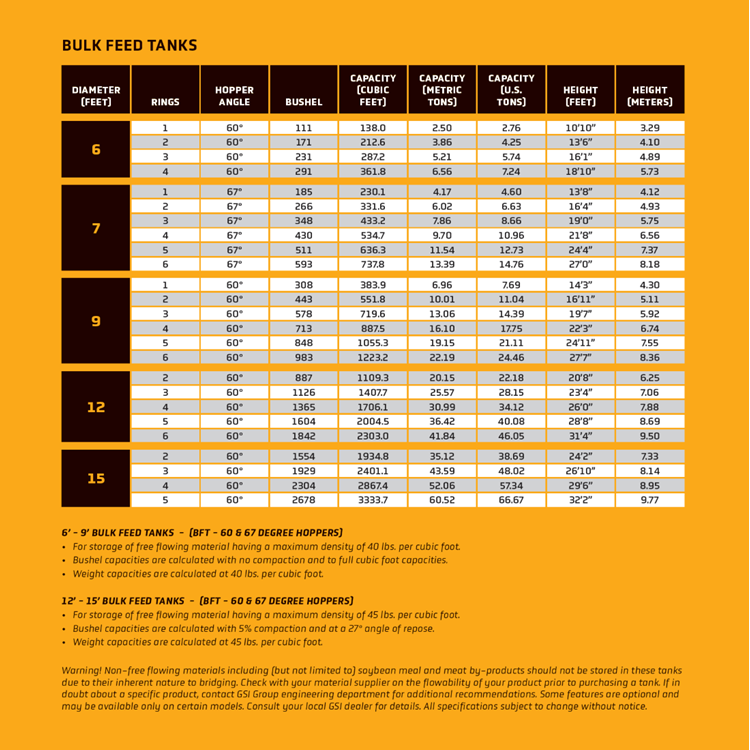

GSI Bulk Feed Tanks are available in 6’, 7’, 9’, 12’, and 15’ diameters and range in capacities up to 2678 bu. (60.52 MT).

THE SOLID CHOICE

GSI precision formed, galvanized coated, high tensile steel sidewall sheets provide outstanding strength and durability. Optional fully die-formed side ladders with dimpled non-skid rungs provide convenient access to the tank.

LEGS & ANCHORS

GSI tanks are supported by our fully galvanized, 6-bend roll-formed legs. GSI legs provide significantly greater strength over simple angle iron legs and greater corrosion resistance and longer life compared to painted legs. Galvanized roll-formed cross ties and two-piece leg anchor sections assist in transferring the tank load to the base and provide greater strength, stability, and support.

FLEX-FLO™ FLEXIBLE AUGER SYSTEMS

Tubing and augers are available in four sizes and five models with capacities ranging from 15 lbs. to 220 lbs./minute. Whether it’s ground feed, crumble feed, mash, high moisture corn, shelled corn or pellets, GSI has the combination to handle it. For corn with up to 27% moisture and other hard to flow materials, GSI also offers a Flex-Flo™ High Roughage system which incorporates a special combination of a 3” (76mm) auger in a 3-1/2” (89mm) tube to reduce plugging.

RIGID AUGER

A complete line of rigid augers and accessories are available for high capacity material handling. In 4”, 6”, and 8” diameters, and lengths from 11’ to 21’, the GSI rigid auger can be configured to meet the most demanding applications, with capacities up to 2100 BPH.

ROTARY UNLOADER

Designed to fit below the 22” Maxi-Flo boot, GSI’s rotary unloaders are available for 2.2” (55mm), 3” (75mm), 3.5” (90mm) and 5” (125mm) Flex-Flo™ or 4”, 6”, and 8” rigid auger systems.

UNLOADER SYSTEMS

GSI offers several unloader systems including single, twin, tandem and twin tandem models. Augers can be direct or belt driven by a 1/3 to 1-1/2 horsepower, totally enclosed fan cooled motor at a standard 358 RPM (other speeds are available for special applications). Additional grain handling accessory equipment is available including extension systems to adjust auger lengths, time clocks, automatic shut-off switches, intermediate drop kits and y-drops. GSI’s 16” (406mm) parabolic boot (available in straight drop or 30˚ models) is made from the very latest in ultra high impact polypropylene for greater flexibility, dependability and durability. The clear poly carbonate version provides a window to confirm that feed is present.

HEAVY DUTY BOOTS

Multiple outlet requirements can be easily handled by our 22” (559mm) all metal boot. This boot, which can be fitted to any GSI grain hopper tank, will allow installation of up to four feed lines in several directions at once.

HOPPER BOTTOMS

Hopper panels are die-formed with rounded corners and sealed edges down-turned for a weather-tight fit. In addition, assembly with rounded, truss-head bolts reduce bridging of contents on inner surfaces. The eave is specially die-formed to conform to the shape of the sidewall corrugation. GSI’s drip lip water deflection system is a one-of-a-kind, roll-formed bottom sheet edge which forces water away from the hopper and lower boot area. Complete weather protection without a loss in capacity.

ALL PACKAGES INCLUDE STANDARD LADDER