Description

Customizable Auger Sections for Bin Filling and Transfer

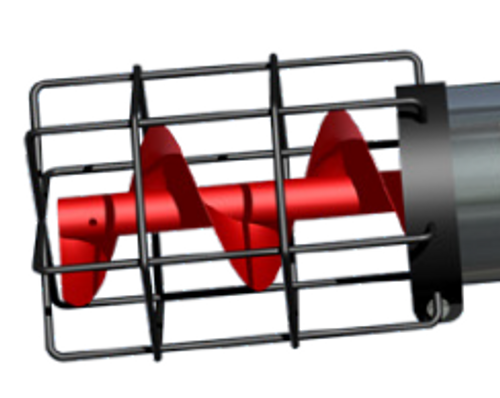

Build or extend your grain handling system with the versatile Haven Industries Grain Saver Auger Tube (SKU: 802-05-1200). Often utilized as bin top fill augers or as sections in custom transfer systems, these multipurpose auger tubes are built to your specified size and length requirements, providing a core component for moving grain efficiently.

Engineered for Flexibility and Durability:

The Grain Saver Auger Tube is designed as a fundamental building block for various grain handling setups:

- Multiple Sizes: Available in common tube diameters of 8", 10", and 12" to match different capacity needs and integrate with existing equipment.

- Variable Lengths: Offered in standard lengths of 5'-65', but can be sized in custom lengths allowing for customization to span required distances, whether filling a tall bin or transferring grain between bins.

- Includes Flighting: Each tube section comes complete with the appropriate diameter flighting installed, ready to move grain.

- Flange Connectors: Equipped with flange connectors at the ends, enabling easy and secure connection to powerheads, other auger sections, hoppers, or discharge spouts.

- Durable Construction: Features a painted auger tube for protection against the elements and wear.

- Powerhead Ready: Designed to be driven by a separate powerhead (electric or hydraulic, purchased separately) matched to the auger size and application requirements.

- Optional Components: Can be integrated with optional components like angle rings for mounting or hoppers (e.g., 30-degree inlet hopper shown as an option) for specific intake needs.

Benefits of the Grain Saver Auger Tube:

- Customizable Solution: Build an auger system tailored to your specific length and diameter requirements.

- Versatile Application: Suitable for bin filling (bin top augers), grain transfer systems, or as replacement sections.

- Multiple Sizes/Lengths: Choose the combination that best fits your capacity and distance needs.

- Ready to Integrate: Comes with flighting and flange connectors for easy assembly with other components.

- Durable Finish: Painted tube provides protection and longevity.

Specify the Haven Industries Grain Saver Auger Tube when you need a reliable, customizable auger section for building or extending your grain handling infrastructure. Remember to select the appropriate powerhead and motor for your chosen configuration.

Technical Specifications (Base Section - Varies with Configuration):

-

Product Name: Haven Industries Grain Saver Auger Tube

-

SKU: 802-05-1200 (Base SKU, specific configuration suffix added based on options, e.g., 802-05-1200-8-5 for 8" Size, 5 Length)

-

Brand: Haven Industries (Grain Saver® Line)

-

System Type: Auger Tube Section (Commonly used for Bin Top Fill Augers)

-

Available Sizes (Diameter): 8", 10", 12"

-

Available Lengths: 5'-65'

-

Components Included:

- Painted Auger Tube (Selected size and length)

- Auger Flighting (Installed, standard type assumed unless specified otherwise)

- Flange Connectors (At ends)

-

Components Required (Sold Separately):

- Powerhead (Matched to auger size and application - e.g., Bin Top Powerhead, Horizontal/Inclined Powerhead)

- Electric Motor or Hydraulic Motor (Matched to powerhead and capacity requirements)

- Intake Hopper (Optional, if needed)

- Discharge Spout (Optional, if needed)

- Mounting Hardware/Supports (As required by installation)

- Electrical Wiring, Controls, and Safety Switches

-

Construction: Painted Steel Tube

-

Flighting Type: Standard (Assumed, verify if other options like cupped or poly are available for this specific product line)

-

Approximate Weight: Listed as 500.00 LBS on the product page, but this seems excessively high for a single section and likely represents a placeholder or a very large configuration. Actual weight will vary significantly with size and length.

Configuration and Compatibility:

Building a system with Grain Saver Auger Tubes requires selecting the right components:

- Size (Diameter): Choose 8", 10", or 12" based on the required grain flow capacity (Bushels Per Hour) and compatibility with connecting equipment (powerhead, hoppers, spouts).

- Length: Select the length or combination of lengths needed to cover the required distance for your application (e.g., reaching the center of a bin roof).

- Power Requirements: Determine the necessary horsepower based on the auger size, total length, incline angle (if any), and desired capacity. Consult Haven Industries powerhead specifications and motor requirement charts.

- Powerhead Selection: Choose a compatible Haven Industries Powerhead designed for the selected auger size and the intended application (e.g., a bin top powerhead often includes mounting for the bin peak).

- Intake/Discharge: Add appropriate hoppers, safety guards/cages for the intake, and discharge spouts as needed.

- Support: Longer auger spans will require adequate support structures to prevent sagging and ensure proper alignment.

- Safety: Ensure all safety guards (belt guards on powerhead, intake guards) are installed and operational. Follow lockout/tagout procedures before maintenance.

Note: This product represents the auger tube with flighting. A complete operational auger requires a powerhead, motor, and potentially other accessories. Always refer to official Haven Industries documentation and consult your dealer for configuration assistance and safety guidelines.